What Is a PRD Pressure Relief Damper? Working Principle and Practical Applications

1. What Is a PRD Pressure Relief Damper?

A PRD (Pressure Relief Damper) is a device installed in ductwork or air pathways to release excess pressure once it exceeds the design threshold. It is a type of safety damper specifically designed for ventilation systems, protecting HVAC systems from damage caused by sudden pressure surges.

Typical applications of PRD dampers include:

- Stairwell pressurization systems.

- Central ventilation ducting.

- Mechanical rooms, clean rooms, and sealed storage areas.

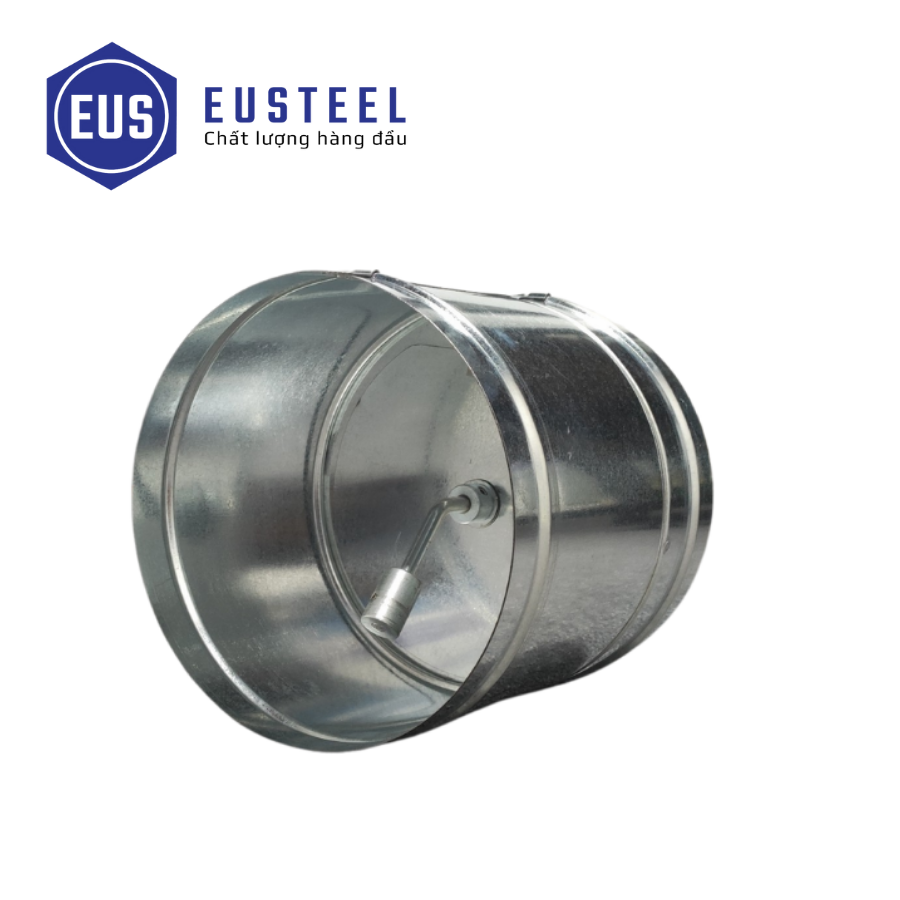

2. Structure of a PRD Pressure Relief Damper

A standard PRD damper usually consists of:

- Damper frame: Made of galvanized steel or aluminum for strength and durability.

- Blades (damper panels): Hinged or pivot-mounted, automatically open when pressure rises.

- Spring mechanism (optional): Adjusts the opening pressure threshold.

- Discharge duct or protective grille: Guides exhaust air safely out of the system.

3. Working Principle of a PRD Pressure Relief Damper

Normal condition:

- Air pressure in the duct remains stable, and the PRD blades stay closed.

- Airflow follows the designed pathway without leakage through the PRD.

When pressure rises above the design limit:

- The force of the excess pressure overcomes the set resistance (gravity or spring force).

- The damper blades automatically open, releasing air instantly to reduce pressure.

- Once the system pressure returns to safe levels, the blades close automatically.

4. Practical Applications of PRD Dampers

PRD dampers are widely used in modern construction and industrial facilities:

Building HVAC systems

- Maintain stable pressure in main duct lines.

- Protect central AHUs and ventilation units from sudden overpressure.

Pressure-controlled rooms – Clean rooms – Technical rooms

- Ensure stable positive or negative pressure according to standards.

- Prevent dust, bacteria, smoke, or toxic gases from spreading in the wrong direction.

Stairwell pressurization systems

- When pressurization fans operate, PRD dampers release excess pressure.

- Prevent doors from jamming or glass from breaking due to high pressure.

Industrial plants – factories – sealed warehouses

- Release accumulated pressure caused by machinery operations.

- Ensure safe and reliable system operation.

5. Advantages of PRD Pressure Relief Dampers

- Fully automatic pressure regulation, no power supply needed.

- Durable, corrosion-resistant, suitable for humid or mildly chemical environments.

- Easy to install and integrate into existing HVAC systems.

- Instant pressure relief, protecting the entire HVAC system and the building.

6. Installation Notes for PRD Dampers

- Select the correct pressure threshold to ensure accurate performance.

- Install the damper facing open space or connect it to a safe exhaust duct.

- Place it at the end of duct branches or sections where excess pressure is likely to build up.

- Perform regular inspections to ensure blades are not stuck or corroded.

Conclusion

A PRD Pressure Relief Damper is an essential component of modern ventilation and pressurization systems. With a simple yet effective operating principle, it helps protect HVAC systems, maintain stable pressure, and ensure compliance with safety standards in residential, commercial, and industrial buildings.

👉 Don’t overlook the PRD damper if you want your ventilation system to run safely, reliably, and in full compliance with technical standards!